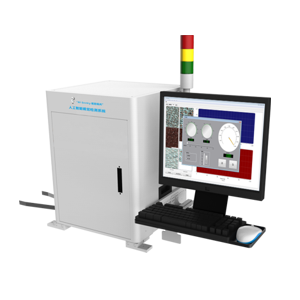

Industry Initiative --"Deep Learning + Machine Vision" Solution

"AI-Sentry" is developed by the innovative special forces in Pumi - "X-VISION Team" for three years. The product uses two branches of artificial intelligence technology, deep learning and machine vision. Through the open editable deep neural network training suite, users can train their own data and perform identification tasks without additional programming. While greatly improving the confidentiality of the production line, it also reduces the various costs that customers need to adjust the testing equipment for different products in the past.

With "AI-Sentry" machine vision software with rich functions, the system can continuously internal calibration, to achieve a virtuous cycle of "template learning detection rich templates more accurate detection more abundant templates more accurate detection". At the same time, "AI-Sentry" background big data system can also classify and summarize the bad points of the problems, output detailed reports, list the problem period, bad categories and other elements, help users adjust the front-end process with objective big data, and improve production efficiency.

Product characteristics

1. Break the closed environment of visual inspection without programming. According to the software "fool-like" prompt, we can complete the template learning and perform the identification task. It's easy to start. Customers can teach AI-Sentry to perform complex identification tasks as needed.

2. Accurate positioning and classification, the accuracy of the system can be better than 99%. AI-Sentry can perform sub-pixel real-time positioning for specified positions, and can distinguish up to 1000 different components at the same time by deep learning intelligent recognition.

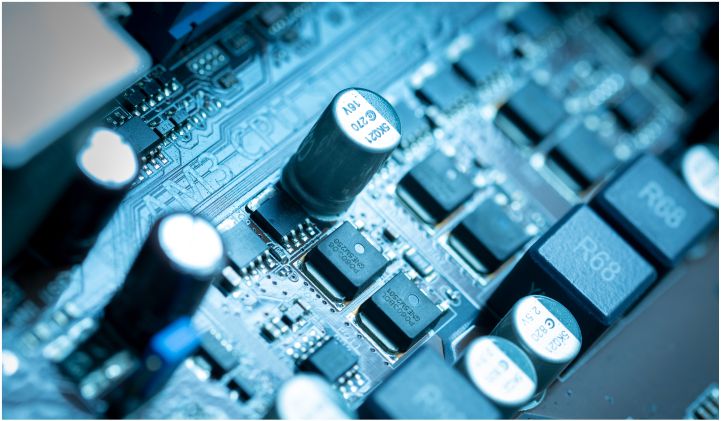

3. AI-Sentry is widely used. In the field of 3C manufacturing, it can be applied to the detection of mobile phone shell, mobile phone accessories, circuit board, screen, electronic materials, etc. It can also be widely used in hardware, food, packaging, automobile and other fields.

4. AI-Sentry system is very compatible. It can run independently on Win7/10 and above platforms, only need to configure NVIDIA unique support. With the exclusive machine vision accessories, the product can be integrated into a complete machine vision system to meet the needs of more customers.

Workflow

The workflow of AI is divided into four parts: making data sets, adjusting parameters, training and testing. The software after training and learning can be used to detect workpieces directly.

A Case Study of AI-Sentry Industrial Application

Mobile phone cover detection

Customer A is a large 3C product manufacturer, undertaking the back panel manufacturing business of many well-known mobile phone manufacturers, with high quality requirements and customer requirements for full product inspection. However, due to the variety of machines and the rapid updating of products, the customer's testing link is under great pressure. In order to solve this problem, Pumis introduced "AISentry" system for customers, which not only helps customers to realize machine vision detection of screw and accessories, but also uses in-depth learning to classify inspected categories, so as to quickly adapt to the changes in machine types and improve efficiency.

Label Character Detection

Customer B is an electronic products manufacturer, which undertakes the manufacturing business of a well-known keyboard manufacturer, and requires a full inspection of many complex items of the products produced. The AI-Sentry system classifies the character missing detection, key brightness detection and key color anomaly detection on the product by studying the deep-seated features of the target to be inspected, and uses machine vision algorithm to carry out the full inspection, which has won high praise from customers.

Keyboard Detection

Customer C is a manufacturer of electronic products, undertaking a well-known keyboard brand manufacturing business, requiring a full inspection of many complex items of the products produced. The AI-Sentry system classifies the character missing detection, key brightness detection and key color anomaly detection on the product by studying the deep-seated features of the target to be inspected, and uses machine vision algorithm to carry out the full inspection, which has won high praise from customers.

Defect Detection of Chopsticks

Customer D is a bamboo chopstick manufacturer, whose products are sold to Japan and require full inspection. By using the AI-Sentry system, Pummy can quickly identify bad chopsticks by learning the deep features of the target to be checked. The green part indicates the external distortion defects of chopsticks, and the red part indicates the internal color defects of chopsticks.