Relay positioning and fitting detection system solution

Testing requirements:

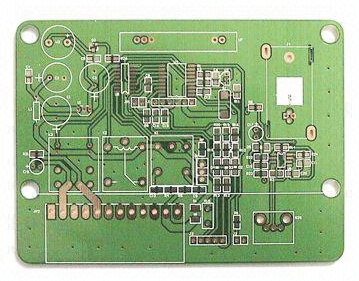

The detection relay locates the hole position on the PCB board and sends it to the movement mechanism to align the position.

Detection accuracy:

The positioning hole accuracy is 0.015mm

The positioning line accuracy is 0.025mm

Machine vision in the relay positioning and fitting detection system application solution configuration:

High resolution standard telecentric lens PMS-TC2-150

Gigabit Network Industrial Camera

POMEAS ring light source

A Machine Vision Inspection Software System Based on POMEAS Developed Independently

Machine vision in the relay positioning and detection system application Solution Description:

Image acquisition module: In the external trigger signal control light source, the camera to obtain and display images.

Set the module: Pomeas professional vision positioning tool patmax for positioning, tool detection accuracy of 1 / 40pix.

Image processing module: by lighting access to pictures, you can specify the region of the image digitized, is conducive to extract the workpiece feature points to be tested.

Control module: can communicate with different kinds of PLC, support various communication protocols such as RS232, RS485, IP-LINK and so on. The detected information can be sent to the next level organization for processing.

Pomeas Optical Technology Company Limited

Manufacturing Center: Dongcheng District, Dongguan City, Guangdong Province on the bridge Industrial Road, Pine Street on the 1st

Tel: + 86-0769-2266 0867 E-mail: marketing@pomeas.com

ADD: 68# Yongwei Street,Bozhuobian Industry Road,East District Dongguan,China.

TEL: 0769-2266 0867

E-MAIL: marketing@pomeas.com