The system adopts the imported high resolution CCD camera, can quickly get the image of the car headlights, through image recognition, analysis and calculation, adopting gray contrast extraction to detect the car headlights blackhead, solder pieces bad, tilt head, crack and other defects.

System Operation Principle:

The product passes the visual inspection system in the same direction;

The photoelectric eye output trigger signal is transmitted to the camera trigger picture after the product is in place.

The software processes the judgment and outputs the OK / NG signal;

The equipment is processed in the next station.

The system uses advanced image visual detection technology, image processing system to pre-process each image, relevant size measurement and other operations, and compared with the standard template image or relevant parameters, according to the detection area of car lights black head, solder pieces bad, head tilt, crack and other gray level difference to extract the surface defects, and prompt defect location and display defect size. Output the corresponding detection signal.

The Main Function of The System:

Automatic image positioning;

The defects such as blackhead, solder lugs, torticollis, cracks and so on are detected.

The product is qualified to give the ok signal, when the product is unqualified, the output ng signal;

The image of unqualified requirements can be automatically saved;

The detection data can be saved for historical data query.

MainTechnical Features:

The operation interface is clear and clear, simple and easy to operate, only simple settings can be automatically performed detection;

The detection software and algorithm are developed independently, and the system is highly targeted; Can selectively detect the local, improve the flexibility of detection;

Specialized light source design, imaging clear and uniform, to ensure that the detection task is completed; The installation is simple;

Compact structure, easy to operate, maintain and expand;

High reliability, stable operation, suitable for various field operation conditions;

Based on PC platform, the system can be extended.

Reference Case

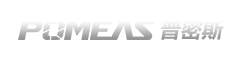

1. The following is the rotor identification system to detect whether the automobile rotor assembly is correct in the assembly process

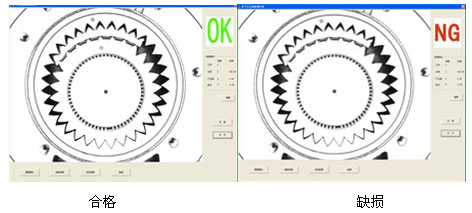

2. The following is the automobile key detection, the main detection is the key character information and surface integrity

Pomeas Optical Technology Company Limited

Manufacturing Center: Dongcheng District, Dongguan City, Guangdong Province on the bridge Industrial Road, Pine Street on the 1st

Tel: + 86-0769-2266 0867 E-mail: marketing@pomeas.com

ADD: 68# Yongwei Street,Bozhuobian Industry Road,East District Dongguan,China.

TEL: 0769-2266 0867

E-MAIL: marketing@pomeas.com